Weldclass PLATINUM Series Products

Weldclass PLATINUM series products offer stand-out performance and unique features, including products such as the legendary PLATINUM GL-11 (Australia's best gasless welding wire), or PLATINUM LT40 burner torches..

View the Weldclass PLATINUM range below, or our check our other product lines; Weldclass original, Weldclass PROMAX series, Weldclass FORCE welding machines & plasma cutters and Weldclass ULTRA welding machines.

-

Complete kit for Oxy/Acetylene gas cutting & brazing. Now available with 7-year warranty. PLATINUM, no quality short-cuts. Manufactured to strict quality-control standards, for performance you can depend on. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Supplied in a robust stainless-steel toolbox.

-

Now available with 7-year warranty. Complete kit for Oxy/LPG (Oxy/Propane) gas cutting & brazing. PLATINUM series, no quality short-cuts. Manufactured to strict quality-control standards, for performance you can depend on. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Supplied in a robust stainless-steel toolbox.

-

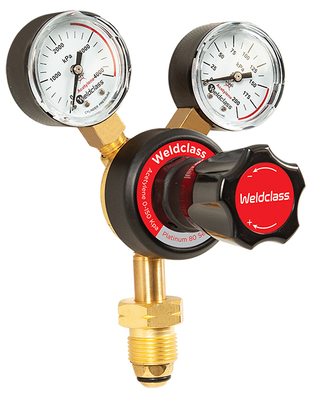

Argon twin-gauge style gas regulator for MIG & TIG welding. 0-28 L/min delivery. PLATINUM series, no quality short-cuts, manufactured to strict quality-control standards, for performance you can depend on. Internal pressure relief valve, and encapsulated seat for safety and reliability. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Now available with 7-year warranty.

-

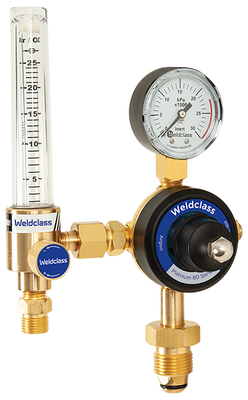

Argon gas regulators with 'bobbin' style flowmeter, for TIG & MIG welding. PLATINUM series, no quality short-cuts, manufactured to strict quality-control standards, for performance you can depend on. Internal pressure relief valve, and encapsulated seat for safety and reliability. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Now available with 7-year warranty.

-

CO2 twin-gauge style gas regulator for MIG welding. 0-28 L/min delivery. PLATINUM series, no quality short-cuts, manufactured to strict quality-control standards, for performance you can depend on. Internal pressure relief valve, and encapsulated seat for safety and reliability. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Now available with 7-year warranty.

-

Now available with 7-year warranty. Oxygen gas regulator for oxy cutting, brazing, heating, etc. 0-1,000 kpa delivery pressure. PLATINUM series, no quality short-cuts, manufactured to strict quality-control standards, for performance you can depend on. Internal pressure relief valve, and encapsulated seat for safety and reliability. Designed and manufactured by a team with over 40 years experience in gas equipment engineering.

-

Acetylene gas regulator for oxy/acetylene cutting, brazing, heating, etc. 0-150 kpa delivery pressure. PLATINUM series, no quality short-cuts, manufactured to strict quality-control standards, for performance you can depend on. Encapsulated seat for safety and reliability. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Now available with 7-year warranty.

-

LPG (propane) gas regulator for use with Oxy/LPG torches, burner torches & other LPG equipment. Fits standard "BBQ" LPG gas bottles/cylinders. 0-300 kpa delivery pressure. PLATINUM series, no quality short-cuts, manufactured to strict quality-control standards, for performance you can depend on. Encapsulated seat for safety and reliability. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Now available with 7-year warranty.

-

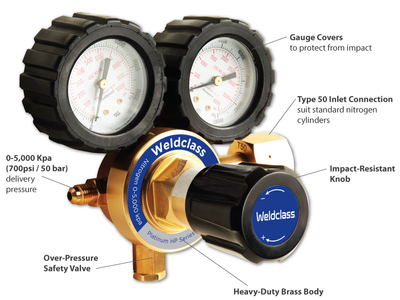

Now available with 7-year warranty. Nitrogen Regulator for applications requiring delivery pressures of up to 5,000 Kpa (700 psi / 50 Bar). Especially suited for HVAC (air conditioning, refrigeration, etc) pressure testing & flushing. Extremely robust design to withstand the rigours of site work: Heavy duty rubber gauge covers protect gauges from impacts, impact-resistant knob & solid brass body. Type 50 (female) inlet connection for fitting to standard nitrogen cylinders. PLATINUM series, no quality short-cuts. Designed and manufactured by a team with over 40 years experience in gas equipment engineering.

If higher outlet pressure is required, see the Weldclass Extra-high pressure nitrogen regulator. -

Now available with 7-year warranty. Extra-high pressure (EHP) Nitrogen Regulator for applications requiring delivery pressures of up to 28,000 Kpa (4,000 psi / 280 Bar). Robust design to withstand the rigours of site work. Fitted with Type 50 (female) inlet for connection to standard nitrogen cylinders and supplied with additional Type 51 inlet for connection to EHP (extra high pressure) cylinders if required. PLATINUM series, no quality short-cuts. Designed and manufactured by a team with over 40 years experience in gas equipment engineering.

-

Now available with 7-year warranty. Blowpipe torch Handles for Oxy/Acetylene & Oxy/LPG cutting, heating & brazing. PLATINUM series, no quality short-cuts, designed with attention to detail & manufactured to strict quality-control standards, for performance you can depend on. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Fits to cutting attachment or heating/brazing mixers.

-

Now available with 7-year warranty. Torch Cutting Attachment for Oxy/Acetylene & Oxy/LPG cutting. PLATINUM series, no quality short-cuts, designed with attention to detail & manufactured to strict quality-control standards, for performance you can depend on. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Fits to blowpipe handles & takes type 41 & 44 cutting tips.

-

Now available with 7-year warranty. Mixers for Oxy/Acetylene & Oxy/LPG brazing & heating. no quality short-cuts, designed with attention to detail & manufactured to strict quality-control standards, for performance you can depend on. Fits to blowpipe handles.

-

Tubes for Oxy/Acetylene & Oxy/LPG heating. Use with heating mixers & heating tips.

-

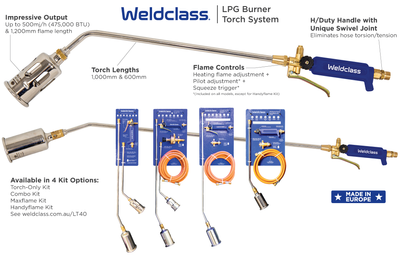

Now available with 7-year warranty. Industrial quality, European-made propane torch for heating and burning almost anything. Choice of 4 torch kits, with torch lengths up to 1m & impressive heat output up to 500mj/h (475,000 BTU). Use with 4/9/45kg LPG bottles with standard "POL" fitting. Heavy-duty handle with unique swivel connection eliminates hose torsion. Common 5/8" UNF hose connections for ease of repair.

Used for; weed burning, metal & weld pre-heating, bitumen/concrete heating, linemarking, roofing, water-proofing, heat shrinking & much more.

Click "More Info" tab below for full details & specifications, or download a pdf fact sheet here. -

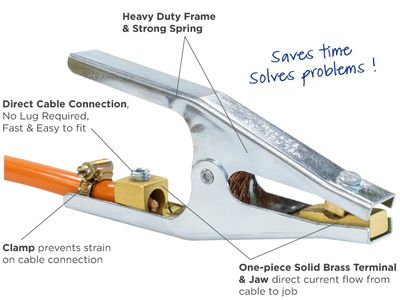

Weldclass PLATINUM series direct fit earth clamps are designed for very easy fitting and long life. No cable lug required, just wire the cable directly to the clamp. Robust heavy-duty build for extended service life. One-piece, solid brass cable terminal & jaw assembly for direct current flow from cable to the workpiece, minimising current leakage and issues caused by poor earthing. Commonly used on welders from 150 to 600 amps.

-

Heavy duty earth/ground clamp for use on welders up to 600 amps. Large alligator style.

-

Solid brass earth/ground clamps. Suitable for heavy use & high-duty cycle applications. G-clamp style for firm attachment and reliable earth connection.

-

Now available with 7-year warranty. Specially developed for use with Plasma cutting machines, the PLATINUM Z-20 high performance Air Filter is a superior alternative to traditional "roll" type filters. PLATINUM Z-20 will filter water, dust, oil and particles down to 1-micron and is virtually maintenance-free thanks to the self-draining feature and super long-life filter cartridge/element.

Using a Z-20 filter will help to increase plasma consumables life, reduce operating cost, improve cutting performance & reduced the likelihood of torch & machine malfunction.

A highly recommended accessory for all plasma cutters.. & other applications where air quality is critical.

Click here to read why proper air filtration is critical for plasma cutting, and how the PLATINUM Z-20 compares to other filters. -

Standard TIG welding gloves? Think again! PLATINUM TG-21 gloves are preferred for their excellent dexterity/feel, great fit/comfort and superior construction. Using a unique proprietary grain leather, this glove offers "the best of both": great comfort/feel AND good heat resistance & long life. Special pattern which comfortably fits most hand sizes.

-

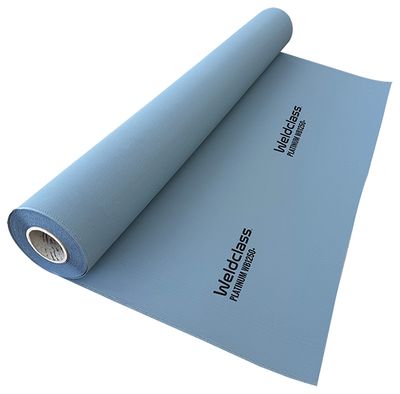

Not your average welding blanket ! PLATINUM WB1250+ is a 'next generation' high-temperature fabric with a high-tech proprietary coating that provides superior performance and safety/ergonomics. This allows PLATINUM WB1250+ fabric to be lightweight, whilst offering protection and durability that is superior to other much thicker & heavier fabrics. Provides max working temperature exposure of 1200°c and up to 1600°c short duration exposure.

Unlike most other high-temperature welding blankets / fabrics, PLATINUM WB1250+ is completely non-irritant, does not shed dust or raw fibres, and is very safe and comfortable to handle. Resists fraying and can be easily cut to any required length or shape.

Blanket Selection Chart Blanket Range Pdf -

A seriously smooth and easy-to-use general-purpose electrode for welding steel. Platinum 12V welding rods are preferred by welders across Australia for their superior arc characteristics, all-position capability (including vertical down), low spatter and easy de-slagging. Great for mild and galvanised steel. Available in 2.0mm, 2.6mm (2.5mm) & 3.2mm. Specifications: AWS A5.1 E6013 / AS/NZS 4855 - B-E43 13 A.

Stick Electrode Selection Chart -

Hydrogen controlled ("low hydrogen") E7016 series stick welding electrodes with a special Twin Flux Coating for superior arc stability - in Foil-Sealed 2KG Vacuum Packs. Commonly used for mild or high strength steel, where the joint requires higher strength than regular "GP" electrodes, such as highly restrained joints or components subject to higher load stress. Also used as a buffer layer prior to hard facing. 16XT welding rods are All-Positional (except for vertical down), easy striking & smooth running, with low spatter & easy slag removal. Available in 2.5mm, 3.2mm & 4.0mm. AWS A5.1 E7016 H8 & AS/NZS 4855: B E4916 A U H10 classifications.

Stick Electrode Selection Chart -

316L series Stainless-Steel welding rods for general purpose welding of matching 316, 316L & other common stainless steels, including; 300 series, 301, 302, 304, 304L, 3Cr12, 409, 444. All-positional (except vertical-down), smooth arc, low spatter, excellent slag control/detachability and high quality weld appearance. Classification: AWS E316L-16.

Available in 1kg re-usable packs & blister/handy packs, in 2.0mm, 2.6mm or 3.2mm.

Stick Electrode Selection Chart -

Platinum 309MoL is a very versatile 309 series stainless-steel welding rod, suitable for strong, tough & corrosion resistant welding of; Dissimiliar steel to stainless, matching 309/309L stainless-steels, CrNi & CrNiMo stainless-steels and hard-to-weld steels. Addition of 2.5% molybdenum (Mo) makes this electrode popular for welding clad steel (such as ferritic steel and Cr-Mo steel clad with 316/316L stainless-steel). Also used for buffer layers. All-positional (except vertical-down), smooth arc, low spatter, excellent slag control/detachability and high quality weld appearance. Classification: AWS E309MoL-16. Supplied in a 1kg re-usable convenience pack to keep electrodes in good condition.

Stick Electrode Selection Chart -

High-performance hard-facing welding rod, ideal for ground-engaging equipment. Platinum 943 deposits extremely hard, abrasion resistant CrNb carbides, offering long wear life with both exceptional abrasion resistance and impact strength. Ideal for hard surfacing applications where resistance to high or extreme abrasion (in particular sliding abrasion) and moderate to heavy impact are required.

Due to the nodular shape of the complex carbides, Platinum 943 deposits are capable of withstanding heavier impact levels than standard chromium-carbide electrodes. Typical applications include; buckets, lips, screws, hammers, teeth, crushing equipment, etc. Typical hardness 60-65 HRC (1st layer). Supplied in a 1kg re-usable convenience pack to keep electrodes in good condition.

Stick Electrode Selection Chart Hardfacing Selection Guide -

312 "universal" series weld-all style electrodes (welding rods) for high-strength and crack-resistant welding of almost any steel or stainless-steel, including dissimiliar metals. Ideal for; Unknown steels, Dissimilar steels (eg steel to stainless), Die or tool steel, etc. (Not recommended for cast iron). Classification E312-16.

Available in 1kg re-usable packs & blister/handy packs, in 2.6mm & 3.2mm.

Stick Electrode Selection Chart -

Popular and versatile NiFe-Cl type cast iron welding rod for high strength, hot or cold welding of; cast iron to itself (incl. grey / malleable, nodular, SG & austenitic cast irons) and cast iron to steel. Machineable weld deposit. Extremely soft, smooth arc with low spatter. Weld metal is stronger and more resistant to solidification cracking than the pure nickel electrode types (such as Ni-Cl). Classification: AWS ENiFe-CL. Available in blister/handy packs & 1kg re-usable packs, in 3.2mm.

Stick Electrode Selection Chart -

D100 (100mm) 0.9kg spools. Premium ER70S-6 series wire for welding steel.

-

Premium ER70S-6 grade MIG (GMAW) wire for welding steel. Platinum series, no quality short-cuts: Manufactured with strict quality-control, layer-wound for reliable wire feeding.