Weldclass PLATINUM Series Products

Weldclass PLATINUM series products offer stand-out performance and unique features, including products such as the legendary PLATINUM GL-11 (Australia's best gasless welding wire), or PLATINUM LT40 burner torches..

View the Weldclass PLATINUM range below, or our check our other product lines; Weldclass original, Weldclass PROMAX series, Weldclass FORCE welding machines & plasma cutters and Weldclass ULTRA welding machines.

-

Premium 316Lsi grade MIG (GMAW) wire for welding 300 & 400 series stainless-steels. Platinum series, no quality short-cuts: Manufactured with strict quality-control, layer-wound for reliable wire feeding.

-

Premium 309LSi grade MIG (GMAW) wire for welding matching 309 stainless-steels, and dissimiar "300 series" stainless to mild steel. Platinum series, no quality short-cuts: Manufactured with strict quality-control, layer-wound for reliable wire feeding.

-

Australia's number one gasless mig wire (self-shielded welding wire) for welding without gas. PLATINUM GL-11® is the first choice of welders across Australia and beyond. Seriously smooth arc, easy-to-use, low spatter, low fume, easy de-slagging, multi-pass and all-positional. Great for mild and galvanised steels. E71T-11 classification. Available in 0.8mm, 0.9mm, 1.2mm, 1.6mm - 4.5kg and 15kg spools.

PLATINUM GL-11® gasless wire is used and reviewed by thousands of Aussie welders every year, with an average rating of 9.67 out of 10. Click 'reviews' tab below to read feedback from other users. -

Flux-Cored (FCAW) 'MIG' welding wire with excellent operator appeal; smooth, stable arc, low spatter, easy de-slagging, all-positional. PLATINUM 71-XM offers hassle-free performance for minimal down-time and maxinum efficiency. E491/E71 T1 C/M classification, for use with both Ar+CO2 mixed, and CO2 gases. Commonly used for welding mild and high strength steels (490Mpa class), heavy construction, mining & earth moving equipment, etc.

-

Long-Life hardfacing 'MIG' wire for ground-engaging equipment. Very high resistance to abrasion with up to 3-4 times better wear life vs other common hardfacing wires* thanks to high Cr content (~26%) and special additives.

Recommended for metal-to-earth applications where wear is mostly caused by abrasion, with low-to-medium impact; points, tynes, buckets, teeth, screws, augers, grousers, etc.

Gasless wire for easy application. Available in 1.2mm in 15kg or 4.5kg spools. Requires minimum 140 amps, suitable for use with 200A-250A MIG welders.

Classification: AS/NZS 2576: 2360-B7

Hardfacing Selection Guide -

SD-980 hard-facing MIG welding wire is a versatile and easy-to-use "all-rounder". Being a solid wire, PLATINUM SD-980 is easy to apply and is all-positional. Ideal for applications where abrasion resistance is required, and especially when accompanied by shocks and blows. The weld can handle abrasion, moderate-to-high impact and metal-to-metal wear. Commonly used on excavator buckets and teeth, screws and augers, tracks, crushing jaws/wheels, etc. Available in 1.2mm in 15kg or 4.5kg spools. Requires minimum 120 amps. Use with Ar+CO2 mixed gas.

Classification: AS/NZS 2576: 2455-M1

Hardfacing Selection Guide -

Extreme performance hardfacing 'MIG' wire, providing a unique combination of both extreme abrasion resistance AND high impact resistance. Up to 6-7 times better wear life vs basic hardfacing wires*... thanks to special carbide additives not found in other wires.

Suitable for a very wide range of applications such as; components subject to abrasion together with high impact stress, where down-time cost is high and longer service life is critical for reducing costs, and where the exact nature of wear is not known in advance and all-round abrasion + impact protection is needed.

Typical applications include: metal-to-earth, ground-engaging equipment, crushing, dredging, mining equipment, grizzly bars, and much more.

Gasless wire for easy application. Available in 1.6mm. Requires minimum 160 amps, suitable for use with MIG welders around 200A-250A & above.

Hardfacing Selection Guide -

Designed to suit the Weldclass Ultra 220MP Pulse MIG welder, the PLATINUM PP365 is a European made & designed 8m push-pull torch offering superior quality and ergonomics to reduce operator fatigue.

Thanks to an advanced Swiss-made digital motor, the PP365 handpiece is more compact and up to 1kg lighter than other torches on the market. The motor is also more powerful than traditional motors for reliable wire feeding.

Takes BZL 36 series front-end parts & comes with both 180-degree straight neck and 30-degree bent neck. -

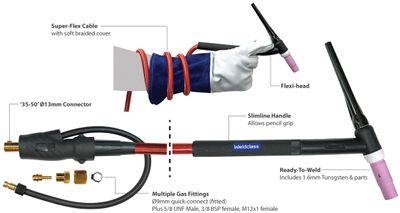

PLATINUM TK Super-Flex series torches offer exceptional flexibility and control, even in the most delicate and demanding TIG applications. Designed for use on professional TIG welding machines (such as AC/DC), where a light weight, flexible and slimline / low-profile torch is preferred.

Can be used together with a foot controller/pedal, or as a switched torch using the optional trigger kit.

Features highly flexible 1-piece cable with soft braided cover, flexi torch head, parts kit, and a range of gas fittings to suit most machines/models. Available in #17 series and #18 water-cooled series.

TIG Torch Selection Guide -

PLATINUM PX series TIG parts feature glass cups / nozzles, and are available as complete kits or individual replacement parts. High-temperature glass cups provide superior arc visibility compared to ceramic cups, benefiting experienced and beginner operators alike.

Fit to common 17/18/26 series torches, premium parts designed for consistency and long-life, no quality short-cuts. Also compatible with Unimig pyrex series.

Parts kits include compact storage box, to easily fit in any toolbox or hang on pegboard/slatwall, with images and part numbers for easy identification and re-ordering. -

The high-performance, All-metal tungsten! Weldclass RE4 purple-tip TIG Tungsten electrodes are suitable for both DC (Steel, Stainless steel etc) and AC (Aluminium) TIG welding. Maintains tip shape, reliable arc striking, low burn off rate, long service life and smooth/stable arc.