TIG Tungstens - RE4 (Rare-Earth) AC/DC

KEY FEATURES

- Universal: "All metal" Tungsten Suitable for DC (Steel, Stainless steel etc) and AC (Aluminium)

- Convenient: Replaces virtually all other types of Tungstens, including; Thoriated (red tip) & Zironiated (white tip)

- Safe: Unlike Thoriated (red tip) tungstens, does Not contain radioactive elements = No special safeguards required for use, storage or transport

- High Performance: Maintains tip geometry, reliable arc striking, low burn off rate, long service life and smooth/stable arc

APPLICATION INFO:

- DC welding of mild steel, stainless steel, copper and chrome molly

- AC TIG welding of: Aluminum alloys and Aluminum bronze

WHAT ELSE?

- A Hazard-Free (non-radioactive) Replacement for Thoriated electrodes

- Also replaces Zirconiated, Lanthanated and other electrodes

- Purple (Turquoise) Colored Tip

- Contains additives/combinations of "rare-earth" oxides, scientifically balanced to provide optimum arc characteristics and wear life

- Compared to other tungsten formulas: Requires less energy to start, Runs cooler, Longer Electrode Life, Greater current capacity (ability to use a smaller-diameter electrode for the same job or use higher current for a similar-sized electrode)

Material Thickness vs Amps vs Tungsten Size

Because of the many variables in any given TIG welding application, there is no single formula to say "for X thickness you need X amps".

The many factors that influence this include; material being welded, type of tungsten elecrode used, type of weld joint, weld position, operator technique, skill and/or experience, required strength or quality of the weld joint, etc.

However, here is a rough guide for TIG welding of steel, stainless or aluminium:

| Material Thickness* | Suggested Tungsten Size* | Amps Required* |

| <1mm | 1.0mm | 10-30A |

| <2mm | 1.6mm | 30-80A |

| 2-3mm | 2.4mm | 80-150A |

| 4-5mm | 3.2mm | 150-200A |

*This is a general guide only and should not be used as specific advice for any particular application

Downloads

The TIG Welding Process - your questions answered

What is Scratch-Start, Lift-Arc and HF Ignition?

All TIG welding articles

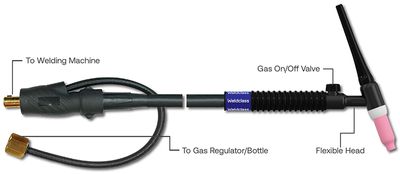

TIG Torch Selection Guide - choosing the right TIG torch

TIG Parts Explained - what goes where on a TIG torch

Weldclass TIG Torches and Spares Catalogue pdf

Weldclass Full Product Catalogue pdf

Not sure if it's me or these rods but I seem to be able to weld better with these rods and the tip seems to stay intact. I mainly weld aluminium and have also tried other brands with Ceriated / lanthanated / zirconiated but having differing quality/tip problems.

26/01/22 8:12 PM