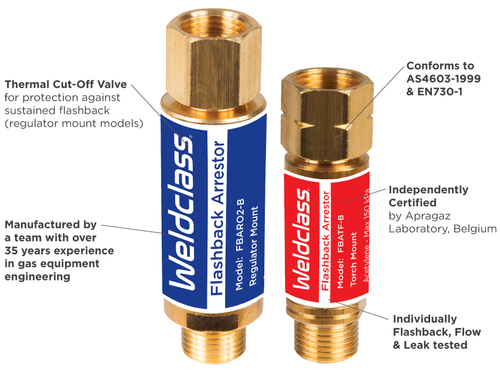

Flashback Arrestors

Protect personnel & equipment from the dangers of a flashback. Regulator and Torch mounted Flashback Arrestors for Oxy, Acetylene & LPG gas cutting & heating equipment. Conform to Australian standard AS4603 and independantly certified by Apragaz laboratory in Belgium, Europe. For peace of mind, every flashback arrestor is flame, flow & leak tested after manufacture. Designed and manufactured by a team with over 40 years experience in gas equipment engineering. Medium flow rate, with up to 35% higher flow capacity* to suit a broad range of applications, including cutting, gouging, brazing and light-to-medium heating.

Got more questions on Flashback Arrestors? Click here to find out how they work, what the safety requirements are & more!

Got more questions on Flashback Arrestors? Click here to find out how they work, what the safety requirements are & more!

Also Known As:

Arrestor for Flash Back, Flashback, Flash-Back, Spark Arrestor

Disclaimer:

*Up to 35% higher flow capacity vs some other brands of standard model arrestors. See more info and downloads tabs for further details.

P4-FBARO2 106.02

KEY FEATURES:

- Conform to AS4603-1999 & EN ISO 5175-1

- Medium flow rate, with up to 35% higher flow capacity*, suitable for broad range of applications

- Individually Flashback, Flow & Leak Tested, for Peace of Mind

- Independently Tested & Certified by Apragaz Laboratory, Belgium

- Thermal cut-off valve for protection against sustained flashback (regulator mount models)

ONE MODEL COVERS MOST GENERAL APPLICATIONS:

- Unlike some other brands/models, Weldclass flashback arrestors cover both low/standard and medium/mid flow applications in one model

- Medium flow rated as a standard feature, not an optional extra or additional cost

- Convenient and simple: one model covers most general applications

- Up to 35% higher flow capacity than some other brands/models*

- Suitable for broad range of applications, including cutting, gouging, brazing, and light-to-medium heating

- Recommended for applications where torch/tip oxygen gas consumption is up to 500L/min**

RELATED INFO & ARTICLES:

- Flashback Arrestors: How do they work? What are the safety requirements? Read more here

- Oxy Equipment Visual ID Guide - cutting, gouging, brazing & heating equipment

*Vs some other brands of standard model arrestors.

**For very heavy heating applications exceeding torch/tip oxygen gas consumption of 500L/min, high-flow arrestors are recommended. Weldclass does not currently offer high-flow arrestors.