Flashback Arrestors - your questions answered

Your questions answered on Flashback Arrestors for Oxy, Acetylene and LPG/Propane equipment

1. What is a FLASHBACK and why is it dangerous?

When a flashback occurs, the flame burns rapidly ‘upstream’, generally causing a loud explosion. If un-checked it can continue through the torch into hoses, regulators and gas bottles/cylinders.

Causes that can trigger a flashback include: Worn or improperly maintained Equipment, Operator Error, improper monitoring of cylinder pressures, and many other causes!

The consequences of a flashback can vary from slight Equipment Damage through to a major gas cylinder explosion resulting in death, injury and/or extensive property damage.

There is no way of predicting just how severe the effects will be, which is why you need to protect yourself against a flashback.

2. What is a FLASHBACK ARRESTOR (FBA) and what does it do?

A flashback arrestor is designed to contain a flashback, and prevent it from penetrating into “upstream equipment” (e.g hoses, regulators and gas cylinders).

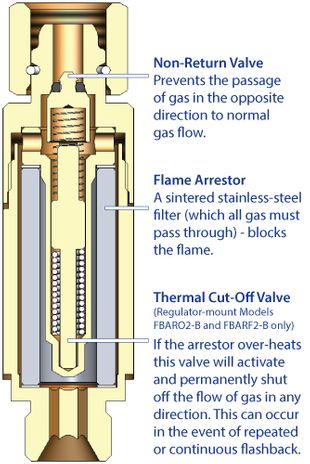

The main parts of a WELDCLASS® Flashback Arrestor and their functions are;

- Non-Return Valve: this stops the reverse flow (back surge) of gas

- Sintered Flame Filter: this blocks the flame

- Thermal Activated Cut-Off Valve: (fitted to regulator mounted models only). In case of a sustained (continuous) flashback or backfire, this valve will close and stop the flow of gas in any direction.

3. What are the current safety requirements?

The Australian standard AS4839-2001 (“The safe use of portable and mobile oxy-fuel gas systems….”) calls for the use of flashback arrestors (see Clause 7.3). Because of this standard, flashback arrestors are a mandatory requirement according to Health and Safety Authorities in Australian states and territories.

4. So….Why should I fit flashback arrestors?

Ask yourself “can I afford not to fit flashback arrestors?”. If you don’t have flashback arrestors fitted to your oxy equipment, you are exposing yourself many risks, including;

- The potential ‘physical’ consequences of a flashback: Equipment and property damage and injury to persons and/or death

- Breach of OH&S / WHS regulations and requirements

- Potential legal and financial consequences of a flashback; litigation, insurance cover ‘disqualification’, etc

5. Don’t fool yourself…. It can and does happen!

This photo demonstrates the damage that can occur from an explosion involving gas cylinders.

6. So, how many flashback arrestors do I need, and where should I fit them?

Australian Standard AS4839-2001 (“The safe use of portable and mobile oxy-fuel gas systems….”) specifies that for “optimum” protection, Flashback Arrestors should be fitted to:

-

Both the regulator and the torch

-

Both the oxygen line and fuel gas (Acetylene or LPG) line

For full details refer to AS4839-2001, Clause 7.3

7. What gases require flashback arrestors?

Oxy-Fuel Systems:

There is potential for flashback to occur with any oxy-fuel system, whether you use oxy-acetylene or oxy-LPG (oxy-propane). The flashback can occur on either the oxy or the fuel gas line, which is why FBAs should be fitted to each gas line.

LPG / Propane only systems (without oxygen):

The risk of a flashback when using LPG/propane-only torches & equipment is extremely low, and using FBAs is not currently required in / by any Australian-standard. However, some work sites may still require FBAs to be fitted to all gas/flame equipment, regardless of whether or not oxygen is being used.

8. Are all Flashback Arrestors the same?

No!

Here's what you need to look out for to ensure that the flashback arrestors you choose will protect you and perform when you need them to;

Compliance with AS4603

AS4839-2001 (“The safe use of portable and mobile oxy-fuel gas systems….”) also specifies that all Flashback Arrestors must be manufactured according to the Standard AS4603. This is very important, because if an arrestor does not comply to this standard, there is no guarantee that it will stop flashback!

If you are purchasing flashback arrestors, or if you already have them fitted to your equipment, always check the labels to make sure they comply to Australian Standards AS4603. If you own flashback arrestors, and you cannot determine that they comply with AS4603, do yourself a favour: Dispose of them and fit Arrestors that do comply.

Independently Tested / Certified

AS4603 states that to be compliant, FBAs must be tested by an independant qualified 3rd party. If the FBA has been independantly tested, normally this will be indicated on the label or packaging.

Weldclass Flashback Arrestors are independantly tested / certified by Apragaz laboratory (Europe), and this is clearly indicated on the packaging and on the FBA itself.

Thermal Cut-Off Valve

This is an important safety feature, however not all FBAs have a Thermal cut-off valve. In case of a sustained (continuous) flashback or backfire, if the internal temperature of the FBA reaches an unsafe level this valve will close and stop the flow of gas in any direction. Without this feature, if a sustained flashback occurs there is a risk that the FBA will fail.

AS4839-2001 also specifies that for optimum protection, regulator-mounted Flashback Arrestors should have a thermal cut-off valve. The label on the FBA will indicate if it has a thermal cut-off valve. Sometimes this is shown via a "[TV]" symbol.

If you cannot see any reference to a thermal valve (on the regulator-mount FBA) on the label, then you can assume that it does not have this safety feature.

Weldclass regulator-mounted Flashback Arrestors include a thermal cut-off valve.

Flow-Rating

Becuase the gas has to pass through a flame filter and other components, every Flashback Arrestor will restrict gas flow to some extent. This means you need to be aware of the flow rating for the FBAs you are using, to ensure they will allow sufficient gas flow for the work your are doing.

Many 'standard' model FBAs have a Low flow rating and can be used for light cutting / brazing etc, but are not suitable for tasks that require medium-to-high flow rates such as oxy heating, heavy cutting/gouging, etc.

Weldclass Flashback Arrestors are Medium flow-rated, with up to 35% higher flow capacity than some other standard model FBAs. This makes them suitable for wider range of applications, including cutting, brazing, gouging and medium-to-heavy heating.

WELDCLASS® Flashback Arrestors

-

Conform to AS4603 and EN ISO 5175-1 (formerly EN730)

-

Independantly certified by Apragaz laboratory, Belgium, Europe

- Each FBA is individually flame, flow and leak tested for peace of mind

- Medium flow rating, up to 35% higher flow capacity vs some other standard model arrestors & suitable for wider range of applications

Periodic Testing or Replacement

If you have flashback arrestors fitted, you should also be aware that Australian Standards AS4603 and AS4839 specify that all flashback arrestors must be tested or replaced at least every 12 months, and in the event of a flashback. Testing should be conducted by qualified repairers.

AS4839 also specifies that flashback arrestors must be replaced at least every 5 years.

Many operators are now choosing to replace rather than test – especially given that flashback arrestor costs have generally reduced in recent years. In addition to the cost of testing itself, the disruption and downtime cost involved in dismantling equipment (and waiting for testing to be completed before it can be used again) is often significant and outweighs the cost of replacement units. Also, it is not uncommon for a % of units to fail due to normal 'wear and tear' and require replacement, which then incurs further costs in addition to testing.

While all care has been taken to ensure the information presented is accurate, Weldclass accepts no responsibility for any errors or omissions in this article. The information given is of a general nature only intended to provide readers with a basic overview of the topics presented, does not take into account the specific circumstances of any individual application or situation, may be simplified and/or abbreviated, will not be a complete or exhaustive resource, and should not be used as a substitute for professional advice. All applicable standards (including Australian standards), industry guidelines and regulations should be consulted and followed. E.& O.E.

-

Shaun, see further comments on this above under #7. What gases require flashback arrestors?Date: 26-07-2023Weldclass -

Michael, yes every Flashback Arrestor will restrict gas flow to some extent. See further comments on this above under #8 > Flow-RatingDate: 26-07-2023Weldclass -

Does the use of flashback arrestors reduce the gas flow in normal use?Date: 26-07-2023Michael Douglas Fletcher Building Products -

Are flashback arrestors required for LPG gas bottles (standard BBQ gas bottle) - what if used with a handpiece for heating material for work purposes?Date: 13-07-2023Shaun -

Thank you for all the knowledgable answers to few of my concerns in this forumDate: 10-02-2022Gord Adams Dreamscape Kennels -

Robert, thank you for your question. As mentioned in this article, Australian standard AS4839 specifies that Flashback arrestors should be tested every 12 months and replaced after no more than 5 years. So no, you do not need to replace the arrestors in your kit that have manufacture date of 2020. Whether FBAs are tested "from new" before being put into service is a matter of either personal choice or the policy that your workplace adopts. Similiar to power tools, some workplaces may stipulate that all tools no matter how new must be tested & tagged.Date: 01-12-2021Weldclass -

May i know if there is any suitable flashback arrestors available in the market for use with Natural Gas? The composition of the NG is mainly methane and ethane with <0.2% propane and very minute amount of Nitrogen.Date: 01-12-2021Meng Heng -

what if you purchase a oxy kit that has the all the stuff in there including required the flash back arrestors however the manufacture date says 2020 and its now 2021 do you have to replace the arrestors you have just purchased as new in a kit. regards robertDate: 10-11-2021robert Thorpe V& D engineering -

Molebogi, there are no special requirements for disposal of FBAs, since they do not contain any hazardous materials.Date: 29-05-2021Weldclass Team JWL (Jaymac) -

Thank you for your question Bob. Torch mounted FBAs should have a non-return valve and a sintered flame filter. The thermal activated valve feature is not applicable for torch models, a) it is only required at the regulator, and b) since it is closer to the flame / work area there is risk of the thermal valve being triggered.Date: 29-05-2021Weldclass Team -

I would like to know the safest way of disposing used flashback arrestors, in case you don't have a testing equipment and you decide to change them on yearly bases?Date: 28-05-2021Molebogi Ramatlhakeng -

What functions are required to the Torch-end Flashback Arrester?Date: 12-04-2021Bob Daniels Bobs Home Improvements -

Hello George, thank you for your question. We don't have any data on this, as the chance/liklihood of a flashback occuring will vary from application to application, and even from user to user. Factors such as the type of equipment used, condition of equipment, fuel gas used, operator technique, etc can all influence this.Date: 20-01-2020Weldclass -

Do you have any statistics indicating how often flashback occurs? I'm looking for info for a hazard assessment. This was an informative article, and very informative comment section!Date: 18-01-2020George -

If there is external damage, what other damage could there be?Date: 18-12-2019Owen -

Hello Sachin, a flashback can certainly occur when using LPG (in particular Oxy-LPG equipment) so yes we recommend FBAs for this application alsoDate: 28-11-2019Weldclass -

Is there requirement of flashback arrestor in LGP when using for heatingDate: 28-11-2019Sachin Topworth -

Hello Ravi, Argon gas is “inert” (is not flammable) and therefore does not require the use of flashback arrestors.Date: 25-11-2019Weldclass -

Mohammed, thank you for your question. FBAs must always be installed with gas flow in the direction of the arrow on the label. If the FBA is installed the wrong way around, it will block / stop gas flow altogether.Date: 25-11-2019Weldclass -

May I use oxygen flashback arrestors for argon gas cylinder.Date: 22-11-2019Ravi Gaikwad Blue star Ltd. -

Hi, Is it safe to install the FBA at upward direction. Thanks & RegardsDate: 13-11-2019MOHAMMED ARIF ALI ARABIAN GASES -

Hello A Collins, Weldclass “Fuel Gas” flashback arrestors are suitable for both Acetylene and LPG. You can check out our range of FBAs by clicking on the links in the article above.Date: 01-10-2019Weldclass Team Weldclass -

Can i connect an acetylene fba to my lpg regulator, or do i need to acquire an lpg specific fbaDate: 20-08-2019A Collins -

Hi Laura, a flashback can occur when using LPG (in particular Oxy-LPG equipment) so yes we recommend FBAs for this application also.Date: 26-07-2019Weldclass Team Weldclass -

Do I need flashbacks on my lpg when I have a regulator and using a heat torch?Date: 26-07-2019Laura -

Richard, testing frequency as stipulated in AS4839 is 12 calendar months (not hours of use).Date: 25-06-2019Weldclass Weldclass -

Frequency of Flashback Arrestor testing is stated as 12 monthly. Usage rates vary, is this a calendar 12 months or 12 months of use i.e. 2000 hours of use? Thanks. regards, RichardDate: 20-06-2019Richard Penberthy sharpe engineering pty ltd -

Richard – You are right, there is not a lot of detail in AS4603 to define what a competent person is. Typically this testing is conducted by companies with a FBA testing machine/device – usually these companies will have staff that are trained to use the device (the tests are relatively straightforward). We will email you directly with some further comments on this.Date: 06-05-2019Weldclass Team JWL Marketing Pty Ltd -

The standards etc. state that flashback arrestor testing is to be done by a competent person. What qualification, level of training, trade certification etc. deems a person competent in this area? I've yet to find a definition of what "competent" is. Thanks. Regards, RichardDate: 12-03-2019Richard Penberthy Sharpe Engineering P/L -

James, Chris, thank you for your questions. When using LPG/propane only, the risk of a flashback is a lot lower compared to using LPG/propane with Oxygen. To our knowledge, Australian standards do not specifically demand the use of FBAs with LPG/propane-only equipment. However some work sites and companies do specify that FBAs should be used on all flame equipment, regardless of whether it is with oxygen or not. To 100% protect against all risk of flashback, then we recommend that FBAs are used on all flame equipment.Date: 31-01-2019Weldclass Team -

Whether Falsh back arrestor is required on heating torch which is operated using Butane GasDate: 30-01-2019James WBJV -

Do I need to fit a flashback arestor if I am only using LPG or Propane for a blow torch. With no oxygen or air feed.Date: 27-11-2018Chris PPQ -

Charles, a flashback can occur when using LPG (in particular Oxy-LPG equipment) so yes we recommend FBAs for this application also.Date: 29-08-2018Weldclass -

Tony, thank you for your question. As mentioned in this article, Australian standard AS4839 specifies that Flashback arrestors should be tested (or replaced) every 12 months and replaced after no more than 5 years.Date: 29-08-2018Weldclass -

Hi, whether if we use Liquid Petroleum Gas for any Hot work activities, is it required FBA ?, your advises are more valuable.Date: 28-08-2018charles NPC -

How long does a flash back arrestor last with regular use. How often should I replace themDate: 28-08-2018Tony Baca -

Hello Kailash, Reasons why we recommend FBAs to be fitted to both regulator and torch are: 1) As mentioned in this article, Austrlaian standard AS4839 specifies that for optimum protection, flashback arrestors should be fitted to both regulator and torch. 2) To minimise potential damage or injury from a flashback, it should stopped/blocked as close as possible to the source. The most common source of a flashback is the torch, therefore fitting FBAs to the torch will prevent the flashback from progressing further. 3) If FBAs were fitted to the torch only, this would not provide protection in the event of (for example) hoses or fittings becoming damaged (leaking/cut/ruptured) and a flahback starting "upstream" of the torch. By fitting FBAs to regulators as well, they become the "last line of defence" to prevent the flashback entering the regulators &/or gas cylinders which would potentially cause massive explosion. We trust that this helps answer your questions!Date: 27-08-2018Weldclass -

Please tell me, whether i have to provide flashback arrester on both sides i.e torch side and cylinder side and why. suppose if I provide flashback arrester on only on torch side then it will prevent the backflow and arrest the flashing if any undesirable event happen then why I have to provide flashback arrester on cylinder side.Date: 24-08-2018Kailash -

Damien, thank you for your question. As mentioned in comments below & information above, AS4839-2001 stipulates that FBA's & other equipment must be periodically tested. So for this reason, yes records need to be kept. This could be via tags attached to the equipment or via a register where each item is given an "asset number" and details on servicing are kept in central list/record. Hope this helps!Date: 17-08-2018Weldclass -

Is there a requirement for records to be kept on Oxy/Acet FBA's and equipment?Date: 16-08-2018Damian Clarke Complete Plumbing Contracting -

Paul – a flashback arrestor is arguably more critical for oxygen than any other gas. Many user don’t realise that oxygen is explosive - for example if it comes into contact with grease or oil (inside hoses, torches, regulators etc) this can cause an explosion, which can include flashback and fire. In short – yes flashback arrestors for Oxygen are essential !Date: 14-05-2018Weldclass -

I can understand oxy acetylene gas needing a flashback arrestor BUT why would OXYGEN need a flashback arrestor ?Date: 09-05-2018Paul -

The FBA also required for ARGON cylinder?can you describe what gases cylinder and doesnt need?Date: 07-02-2018mohd azizi abd hadi SIB MALAYSIA -

Thank you for your comment/questions Kumaran. Australian Standard AS4839-2001 (“The safe use of portable and mobile oxy-fuel gas systems….”) specifies that Flashback Arrestors should be tested every 12 months and replaced every 5 years. 12 monthly tests should be conducted by a qualified party and should include flow, reverse flow & leak tightness. We recommend that you refer to AS4839-2001 standard. This can be purchased from https://infostore.saiglobal.com.Date: 03-01-2018Weldclass -

1. Can I know? Is there any expiry date for the FBA? 2. How often We need to check the FBA? 3. And how to check the same?Date: 25-12-2017Kumaran