Earth Clamps… why you will never get a good weld with a bad clamp

The condition, quality and design of an earth clamp is more important than what you might think…

We frequently see many weld quality and welding machine performance issues caused by earth clamps that are either a) in poor condition, or b) a poorly designed clamp. Yes it’s a basic piece of equipment, but it can make all the difference!

First, let’s get this straight:

No, the earth clamp is not just an accessory to hold metal together! ALL the welding current passes through the earth clamp. Without a good earth connection, the performance of the welder and the welding machine will be compromised... this can only mean one thing: an inferior quality weld.

What happens if the earth clamp is in bad condition or poor quality?

If the earth clamp is not in good condition, this will cause welding current leakage or restriction. Or in other words, it will cause a drop in welding output voltage… which is like someone changing the settings on your welder. (If you are MIG welding, for example, the wire speed may seem to be creeping up).

Often the first reaction of the operator is to change the machine settings to compensate, instead of fixing the real cause of the problem.

How does this happen?

Remember; ALL the welding current passes through the earth clamp. Or if you take the cable lug, all the current passes through the lug. If the lug is poorly fitted to either the clamp or the cable, obviously this is going to restrict the welding current.

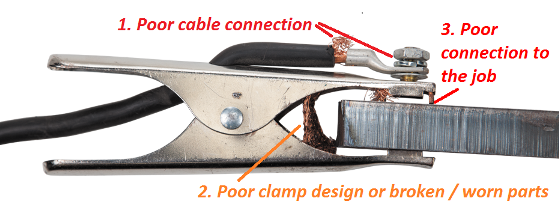

There are typically 3 areas of “connection” on an earth clamp that can cause a current leakage/blockage;

-

Cable to the clamp, usually a cable lug: Lugs are probably the worst offender here! They can be hard to fit properly, cable can pull out of the lug, the lug bolt/terminal can become loose, etc, etc!

-

Within the clamp itself: Broken or worn parts, poor clamp design.

-

Connection of the clamp to the job: Can be compromised through a weak clamp spring, worn or broken clamp jaws, corrosion on the clamp, etc.

... And it only gets worse

Once a “connection” problem in an earth clamp develops, the affected component will then start to heat up. Heat will then accelerate the initial problem, causing further breakdown in the connection, which then causes more heat and so the cycle continues.

Poor connection quality = Welding current restriction = Overheating = Problem gets worse

So what’s the answer ?

-

Do: Check your earth clamp regularly. Make sure the cable lug is fimly fitted and bolted. Replace the clamp if it has deterioriated, eg: weak spring, broken parts, continues to over-heat, etc

-

Don’t: Just give your clamp a shake & re-attach it.. this will not fix the problem

-

Do: Use only good quality, well designed earth clamps.

What is a Good Earth Clamp?

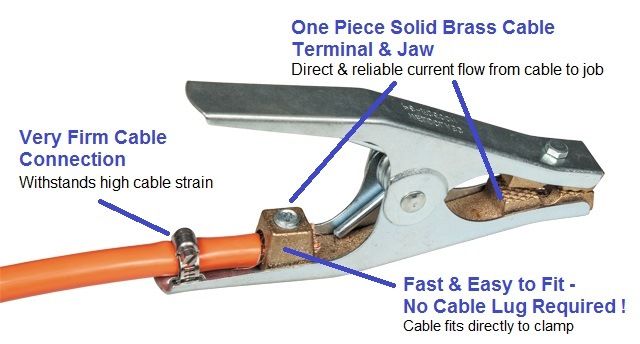

The Platinum EC500H is one of our top selling earth clamps. It’s a simple, yet very effective design that eliminates many of the problems that we have already mentioned. And it’s super easy to fit; no cable lug required!

Click here for more information on the Platinum EC500H clamp

Or View our Full Range of Earth Clamps Here

This blog is intended to help with: Earth clamp and ground clamp problems and issues when MIG, MMA, Stick and TIG welding // Weld quality issues // Why does my wire speed setting change when I’m not touching my machine controls? // Why does my wire speed fluctuate, change, speed up & slow down? // Why does my welding voltage (heat) or amperage settings change when I’m not touching my machine controls // Where can I find buy a good quality heavy duty long lasting earth ground clamp for my welder? // What is the best earth clamp?

-

Also echoing what Kurt said. I know it is often incorrectly called the ground clamp, but it is wrong. Look it up, it should be called a Work Clamp.Date: 24-03-2023Nathanael Vleeskens SIMPEC Pty. Ltd. -

You should correct your verbage. This is NOT called and "earth clamp". It is always called a WORK clamp and a WORK cable, as it is attached to the WORK and can be either positive or negative depending on process. We don't use the term earth, or ground in our secondary welding circuits.Date: 05-12-2020Kurt Kohles HWS -

Hi, can I use earth clamp 500 amps to 600 amps welding machine ? thanks & regardsDate: 21-02-2020Afrizal SMBR