What is the Best Air Filter for Plasma Cutting

The right Air Filter can make a big difference to the performance of your plasma cutter. Here's the pros and cons of some commonly used air filters.

Firstly - Why is Air Purity so Critical when it comes to Plasma Cutting?

When it comes to filtration of the compressed air line feeding your Plasma Cutter - the cleaner the better.

Without filtration, compressed air typically contains impurities including moisture (water), dust particles and oil particles. If allowed into the plasma machine and torch, these impurities will;

- Reduce the life of plasma torch parts/consumables, which increases costs

- Contribute to torch and machine malfunction, which means more troubleshooting and down time

- Accelerate wear of (or even cause damage to) the torch, especially the torch head (expensive to repair!)

- Reduce cutting performance / capacity

The cleaner the air supply (or the better air filtration is), the more these problems are reduced, resulting in;

- Increased plasma torch parts/consumables life & reduced costs

- Reduced torch & machine malfunctions & reduced down time

- Improved cutting performance & capacity

...and don't forget Air Pressure & Flow

This aspect is often overlooked. Along with air purity, consistent air pressure and flow is also critical for optimum plasma cutter performance.

This means that it is important to chose an air filter that not only effectively removes impurities (water/moisture, oil, particles) but also does this with minimal restriction, or interruption, of air pressure and flow.

Are all Air Filters the Same?

No. Read on to find out more about the common filters available, and which type of filter will help you get the best performance from your plasma cutter.

Basic Air Filters/Regulators

Most Plasma Cutters come with an air filter/regulator that looks something like this.

These units provide the minimum level of filtration needed for plasma cutting. Typically they are around 50% efficient, which means they will remove some water/dust/oil particles - but certainly not all.

To achieve optimum performance from your plasma, you need to add a higher-performance filter like the models shown below.

Normally, the existing filter/regulator would remains in place on the plasma machine, and the "high performance" filter fitted as an additional unit.

'Roll' Type Air Filters

Sometimes called "sub micronic" filters (or "toilet roll filters"!), these have a cylindrical cartridge/element.

Pros:

- High-performance - filters out particles smaller than 1-micron

- Inexpensive to purchase

Cons:

- Cartridge/element requires frequent replacement (recommended every 5-10 days)

- High maintenance and ongoing cost

- Not self draining, which allows water/moisture to build up inside the filter

- Cartridge/roll can quickly become saturated, reducing filtration effectiveness, allowing moisture to continue 'downstream' of the filter, restricting air flow & sometimes causing a build up of mould/dirt inside the filter.

- Users are sometimes tempted to use a toilet roll in place of the correct filter. This can result in paper fragments being carried downstream, causing permenant & costly damage to the plasma torch.

Summary:

Roll style filters work exceptionally well when they are properly maintained. However this comes with ongoing cost and inconvenience because the filter element requires frequent replacement. If not properly maintained, they can quickly become ineffective and even detrimental to the performance of your plasma.

'Inline' Air Filters

A compact 'single stage' filter, which incorporates a specially treated plastic filter element. As water touches the surface of the element, the porous plastic closes off to prevent water passing through the element.

Pros:

- Filters particles down to 0.85-micron

- Blocks moisture/water to prevent it passing through the filter element

- Inexpensive to purchase

- Compact & lightweight

Cons:

- When filtering out water/moisture, air flow is also restricted / interrupted due to the filter element design

- As consistent, continuous air flow and pressure are essential for proper function, this restriction can be detrimental to the performance of a plasma cutter.

- Not self-draining, which allows water/moisture to build up inside the filter (requiring manual draining by dismantling filter & replacing or drying the filter element)

- Filter can become saturated relatively quickly due to compact design (reduced capacity) & no drain

Summary:

This filter design is less-than-ideal for plasma use, for two reasons; 1) The water/moisture filtration process also restricts air flow, preventing consistant air supply which is very important in plasma applications. 2) The filter has no drain, allowing water/moisture to build up inside the filter body.

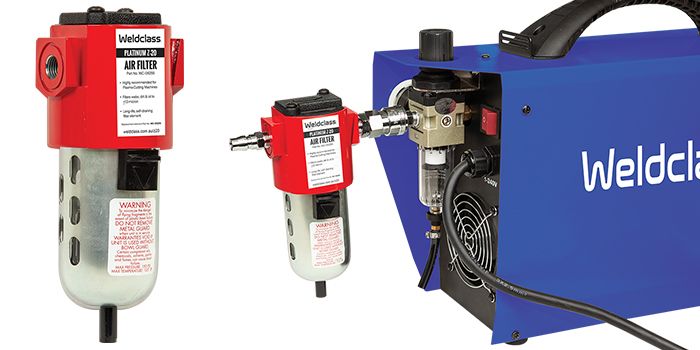

PLATINUM Z-20 Air Filter

The PLATINUM Z-20 is a high-performance Air Filter, specifically developed for use with Plasma Cutting Machines. Designed for highly effecient filtration, consistent air flow/pressure delivery, and very low maintenance.

Pros:

- 99.97% effeciency, filtering water, dirt and oil particles down to 1-micron

- Ultra-long-life cartridge/element lasts up to 6 months

- Delivers clean, uninterrupted air supply (at consistant flow and pressure), even in dirty environments

- Self-Draining, preventing moisture build up / saturation & ensuring the filter remains effective

- Air flow is directed vertically down then upward to remove the bulk of water droplets prior to entering the filter element, increasing the service life of the element

- Removal of moisture is achieved without restricting air flow, to ensure consistant air flow and pressure delivery to the plasma cutter

- Very low ongoing cost

- Does not require frequent inspection or frequent cartridge replacement

- Compact & lightweight design, easy to mount

Cons:

- Purchase cost typically higher than other types of filters (however much lower maintenance / ongoing cost)

Summary:

The PLATINUM Z-20 is our #1 recommended air filter for plasma cutters. While they may initially cost more than some other filters, the ongoing benefits make this unit the best value by far - saving money & hassle in the long term. If you want a filter that is tried and proven and requires very little maintenance... this is it!

PLATINUM Z-20 Air Filters are available from your local Weldclass distributor.

Disclaimer: While all care has been taken, Weldclass accepts no responsibility for any inaccuracies, errors or omissions in the content of this webpage or in any attachments. The information given is of a general nature only and does not take into account the specific circumstances of any individual application. Some information given may reflect the personal opinion of an individual. All product specifications are subject to change without notice. Any comments regarding the intended or suggested application or performance of any product is of a general nature only. It is the sole responsibility of the user and/or owner and/or purchaser to select the appropriate product for their intended purpose and to ensure that the product selected is capable of performing correctly and safely in the intended application. E.&O.E.

-

Hello I have a Cutskill 45 plasma cutter and a Z-20 filter. What regulator should I get.Date: 01-06-2022Sam Rinaudo Buffalo Farm Equipment