Spool and Wire Feed Set Up for 250MST & 220MP MIG Welders

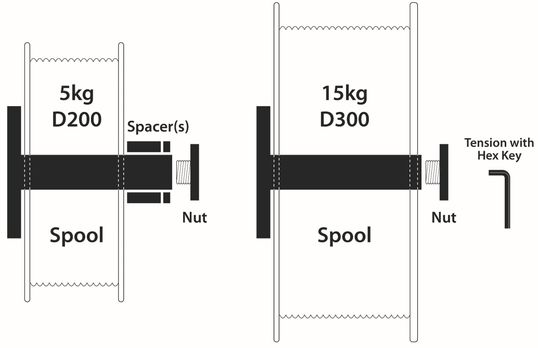

Spool Hub Set-Up

- Install with spool as shown above

- For 200mm / 5kg spools, use spacer(s) as shown above. Use one or both spacers as required, depending on spool width

- Set correct tension on the spool, using hex key. The Spool tension should be enough to brake the spool & prevent free-wheeling. Do NOT over-tighten, as this will put undue strain on the drive system.

Drive Roller Alignment

Each drive roller will have two grooves for different wire sizes. Make sure that the drive roller is installed so that the groove being used is the correct size for the wire size you are using.

VERY IMPORTANT:

Make certain that the wire is sitting directly & firmly inside the groove in the roller, before closing/locking the tension arm.

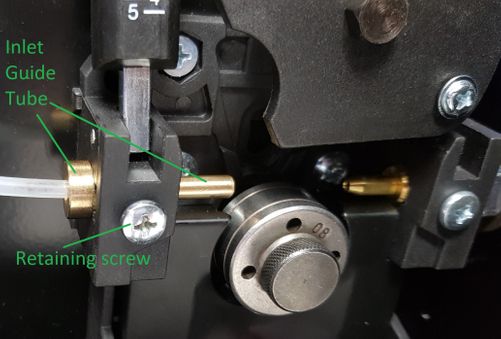

Check the Inlet Guide Tube shown below. If this is slightly crooked, it will prevent the wire from being aligned precisely with the drive roller groove. You may find it easier to sight wire alignment by using the camera on your phone.

If guide tube / wire appears to be mis-aligned: Loosen the retaining screw, remove the Inlet Guide Tube, clean the guide tube and it's locating hole to remove any dirt/debris, then replace and check alignment again.

Related Articles

Wire feed troubleshooting guide

Ultra 220MP Pulse MIG User Guide