Grinding Discs- PROMAX Inox Fast

New look... same legendary disc! Taipan products are being incorporated into the Weldclass family, to reflect our new branding. Rest assured, these are the same awesome grinding wheels that you've come to love!

WHY USE PROMAX FAST INOX GRINDING DISCS ?

- "Fast" Series: Medium Hardness for Fast Grinding of Steel & Stainless-Steel

- INOX (Iron-Free) for Safe Use on Stainless Steel

- Fast Metal Removal, Good Disc Life and Great Value for Money

APPLICATION INFO:

- For Grinding of Steel and Stainless-Steel

- Designed to provide fast metal removal with moderate grinding pressure

- Depressed Centre

- For Angle-Grinders

WHAT ELSE ?

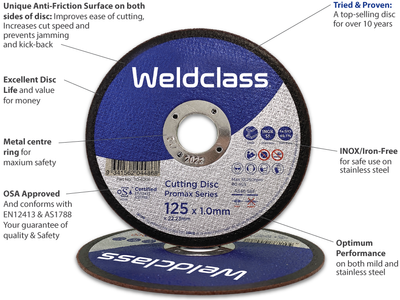

- OSA safety approved & conforms with AS1788.1 & EN12413 standards: Your guarantee of safety & quality

- Promax Series: No Quality Shortcuts, Great Value

OPERATOR INFO:

For optimum performance, apply moderate pressure to push the disc into the work piece, but do not apply too much pressure. Excessive pressure will reduce metal removal and shorten the life of the disc. (If a harder bond disc is required for heavy use, we recommend the 'HD' series grinding disc).

DID YOU KNOW ?

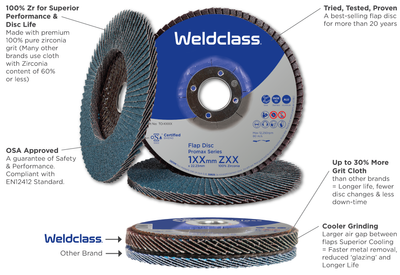

Weldclass discs are developed through a rigorous and demanding process, using CNC testing equipment to test and compare disc performance for R&D and Quality Control. Extensive user trials are also conducted, to determine how the discs perform 'in real life' across a number of performance categories, such as: blade life, grinding speed, ease of use, robustness and resistance to fracture. The result? A fair dinkum, tried and tested product!